Product Support

-

When and why do I need an adapter?

An Adapter is needed to keep the post being driven straight within the driver chuck. Without an Adapter, impact energy is wasted and the post driver drives poorly. See more about adapters >

-

I want to drive “X” feet, will it do that?

This varies depending on soil conditions. If it can be driven with a hand-held, manual post driver – then it should be able to be driven with a Minuteman or Minuteman XL8 post driver.

-

What is the differnce between the Minuteman and Minuteman XL8?

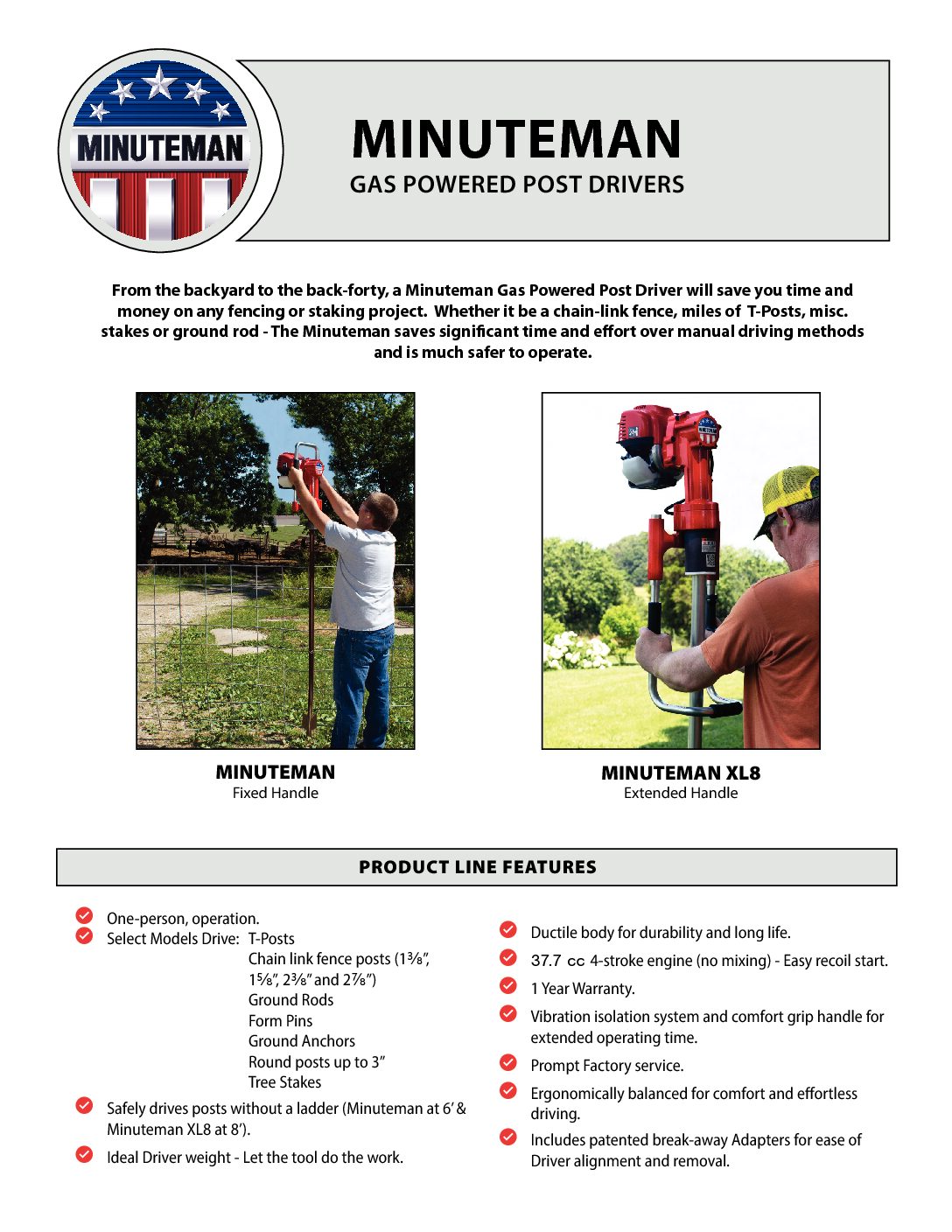

The Minuteman has a fixed handle and can drive posts up to 6 ft in height without a ladder. The Minuteman XL8 has a rotating handle that extends to allow the operator to drive post up to 8 ft. tall without a ladder. Not moving a ladder from post to post shortens installation time and increases project safety.

-

What is the largest post I can drive?

The Minuteman will drive post up to 2” in diameter. The Minuteman XL8 will drive post up to 3” in diameter.

-

Can I drive post instead of putting them in concrete?

-

Do I need special grease?

No. Any EP 0 Low Viscosity lubricant is fine.

-

Where can I have a Minuteman serviced?

Our service team can take care of all your service needs.

Contact them here >

- Potential Issues

-

Post lodged in the driver with adapter installed

Turn off the engine. Unlatch and slide out the locking pin that holds the adapter. Using the handles, lift post driver upward, allowing the adapter to slide out. If the pressure from the flared post does not allow you to lift driver off the post, insert a flat-head screwdriver in between the bottom of the metal chuck tube and the plastic adapter, to pry the adapter downward. Be careful not to damage the inside of the chuck tube. Once loosened, lift using the post driver handles. As the two-piece adapter frees from the chuck tube they separate from the post. Reinsert the adapter, apply the locking pin and resume post driving.

-

Drives post slow or sluggish engine performance

Typically this is resulting from improper driver storage (see below for proper storage) or over-filling the oil causing the oil to seep into the combustion chamber. Turn off the engine. Position the driver vertically; remove the dipstick to check oil level. (See page 6) If you need to remove some oil, dispose of it properly. If oil is at proper level, follow the procedure listed in “Pull-start is frozen or hard to pull.”

-

Pull-start is frozen or hard to pull

This typically results from oil seeping into the combustion chamber from improper driver storage (see below for proper storage) or overfilling the oil reservoir of the engine. Remove spark plug and pull hand grip several times until it pulls freely. Replace the spark plug. Check the oil level in oil reservoir to ensure proper level (page 6). Follow starting procedure. It is not unusual, for blue smoke to be emitted from the engine, let the engine run until smoke clears.

-

Engine trouble is sporadic at half throttle

This can be due to a cold engine start, but it also can occur with a warm engine after the throttle is above half. Check the oil level. If overfilled, follow the steps to remove the oil and refill it. If the oil level is correct and the problem is still present, call Minuteman for service.

-

No longer Driving Post, but Engine is running fine

This usually indicates the piston o-ring has worn flat. Contact Minuteman for service >

-

There is lubricant left on the post after driving

A small amount of residual grease left on the top of the post is normal. Any dime sized globs or larger may indicate an O-ring is flattening or the inner chuck tube is damaged. Contact Minuteman for service >

-

High engine noise/revving without hammer/anvil hitting post

First make sure the Anvil has not become stuck at the top of the inside of the post driver chuck. Using a firm grip on both handles, pick the driver up off the top of the post slightly and bring it back down on the post. Maintaining the contact of the Anvil with the post is important. Running the engine without engaging the Anvil (dry-firing) reduces the life of the driver. Make sure to maintain steady contact and pressure on the post while driving.

-

High engine noise/revving without hammer/anvil hitting post and excessive grease leaking on post

First make sure the Anvil has not become stuck at the top of the inside of the post driver chuck (see above). If there are large amounts of grease ( approx. 3 oz or more) on top of the post being driven the post driver O-rings may need to be replaced. Please contact Minuteman for further instructions on replacing O-rings.

-

Engine is not running properly

Refer to the engine manual that was shipped with your post driver or Contact Minuteman for service >

-

Improper Storage

Do not lay horizontally on the driver’s side or resting on the engine. If the unit cannot be stored securely in the upright position, place the chuck on a flat surface, and lean the driver toward the engine side until it is supported by both the shroud and chuck. In this position, the driver is on an angle with the top handle at the topmost point.

If the post driver will not be in use for 3 months or more, drain the fuel tank of gas, and hang or secure the driver in an upright position with the top handle pointing upwards. When the driver is to be used again, refuel with fresh gas, change the oil, check the fuel filter and spark plug for wear and replace if needed. Check for any loose parts and tighten according to the Owner’s Manual that came with your post driver.

-

Other problems or technical questions

Other problems or technical questions: Document your serial number and contact Minuteman Marketing, Inc. Phone: 309.889.9042, Email: service@minutemanpostdrivers.com.

Owners Manual

Owners Manual  Spec Sheet

Spec Sheet